Where is my serial number?

The engine serial number is on a metal plate, typically found on the left- hand side of the block.

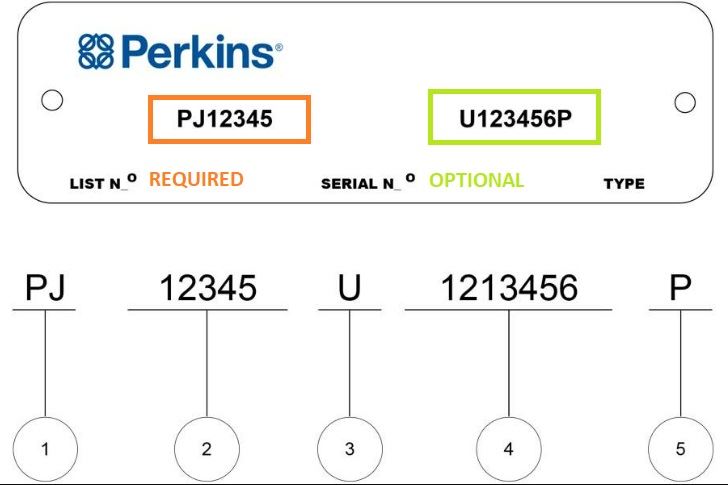

What do I need to enter?

Copy the full 15 or more digits as printed on the engine, excluding any spaces.

The minimum search requirement is the build list, typically 2 to 4 letters followed by 4 or 5 numbers.

Spaces or symbols such as asterisks will not be recognized. Clean and check the plate carefully, as letters and numbers may look similar.

Still need more information?